Another cost effective solution when strength and corrosion are not a determining factor.

Another cost effective solution when strength and corrosion are not a determining factor.

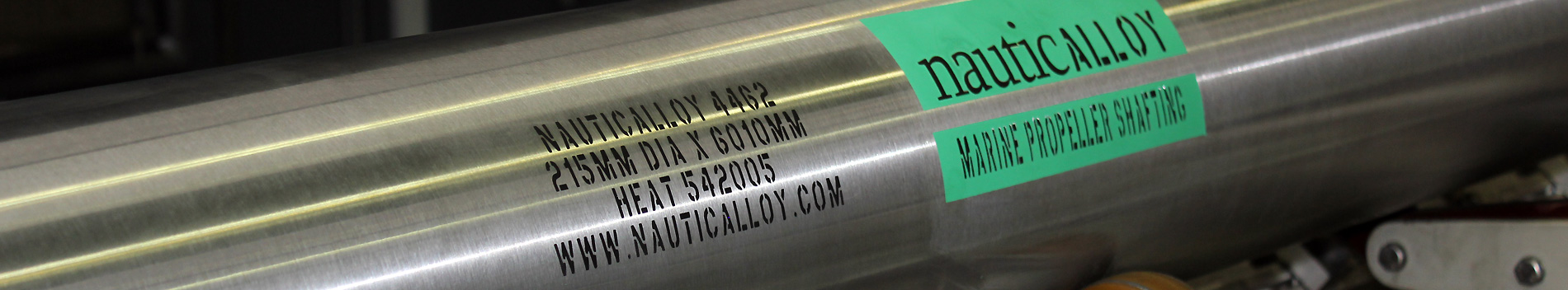

All Nauticalloy produced can be supplied complete with 3rd party Inspection, testing and certification.

All Nauticalloy produced can be supplied with dimensional reports confirming diameter tolerance and straightness.

All Nauticalloy produced has a straightness tolerance up to 80mm dia of 0.005”- 0.010” TIR and 85mm and above we aim for 0.010” TIR. (TIR=Total Indicator Reading)

|

NAUTICALLOY 4307 |

|||||||||

|

Chemical Composition* |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

N |

|

% Values (minimum) |

- |

- |

- |

- |

- |

17.50 |

8.00 |

- |

- |

|

% Values (Maximum) |

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

19.50 |

10.50 |

- |

0.11 |

|

Mechanical Properties |

Proof Strength Rp 0.2 |

Tensile Strength |

Elongation A4% |

Hardness Brinell BHN (Min) |

Red of Area % |

||||

|

Metric Units (Mpa-N/mm2) |

>205 |

515 - 680 |

45 |

<170 |

25 |

||||

|

Imperial Units (ksi) |

>30 |

75 - 100 |

45 |

<170 |

25 |

||||

|

Related Specifications |

304L |

AISI 304L |

UNS S30403 |

1.4307 |

|||||

Download the Nauticalloy 4307 data sheets in a PDF format here.

+44 (0) 1902 409409

+44 (0) 1902 409409